Self-Healing Material Technologies: Roads, Buildings and Machines That Repair Themselves

Advances in material science have accelerated rapidly over the past decade, and by 2025 self-healing technologies have moved from experimental laboratories to commercial use. These innovations aim to extend the lifespan of infrastructure and machinery, reduce maintenance costs, and improve safety across multiple sectors. Modern self-repairing materials use chemical, biological and mechanical mechanisms to restore their structure when damaged, offering a practical response to growing global demands for sustainable and durable solutions.

How Self-Healing Infrastructure Materials Work

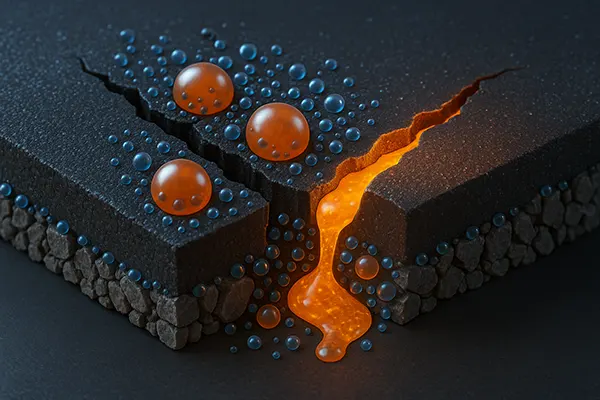

Self-healing materials rely on systems capable of detecting damage and initiating a repair process without human intervention. In construction and road engineering, one of the most widely adopted methods involves microcapsules embedded in concrete or asphalt. When cracks form, these capsules rupture and release healing agents—typically polymer resins or mineral-based mixtures—that fill gaps and solidify, restoring structural integrity. Such systems significantly slow down crack propagation and reduce the risk of major failures.

Another approach implemented in 2025 infrastructure projects involves bacteria-based healing compounds within concrete. These specialised bacterial spores remain inactive until moisture enters a crack. Once activated, they produce calcium carbonate, which naturally seals the gap. This technology has been adopted in several EU-funded road renovation programmes due to its long-term performance and environmentally safe reaction process.

For asphalt surfaces, induction heating has become increasingly common. Metal fibres added to the asphalt blend allow maintenance teams to use electromagnetic induction to heat the material, enabling the bitumen to rebind internally. This method restores the road surface efficiently while reducing the frequency of full-scale resurfacing operations.

Real Applications in European Roads

By 2025, the Netherlands, the United Kingdom and Denmark remain among the leading European adopters of self-healing road materials. The Dutch infrastructure agency Rijkswaterstaat has expanded trials of induction-heated asphalt across national motorways, reporting reductions in maintenance costs of up to 50%. Such systems also decrease traffic disruption, as targeted local repairs take minutes rather than hours.

In the UK, self-healing concrete has been used in bridge repair projects and new highway structures. The University of Cambridge and several engineering firms have contributed to large-scale deployments of bacterial concrete, noting enhanced durability in regions with high rainfall and freeze–thaw cycles. This has proven especially effective in supporting long-term resilience plans for critical infrastructure.

Denmark has integrated microcapsule-based asphalt blends into cycling lanes and urban road networks in Copenhagen. Monitoring from 2023 to 2025 shows reduced surface degradation and fewer maintenance interventions during winter seasons. These results encourage continued investment in self-healing technologies as part of Denmark’s national sustainability strategy.

Self-Healing Technologies in Building Construction

The construction industry increasingly relies on self-repairing materials to enhance the longevity and sustainability of buildings. Concrete structures, which traditionally require significant maintenance due to cracking and weather-induced wear, benefit the most from these technologies. In 2025, commercial property developers have adopted bacterial concrete and polymer-infused mixtures to maintain structural stability with minimal intervention.

Self-repairing coatings also play a vital role in protecting metal and composite surfaces. These coatings contain microcapsules filled with corrosion inhibitors. When scratched or exposed to moisture, they release protective substances that slow down oxidation. This helps preserve building façades, metal frames and exposed architectural components without requiring constant repainting or refurbishment.

Another area experiencing growth is the use of self-repairing insulation materials. Thermal foams with shape-memory polymers regain their form after impact damage, ensuring buildings maintain consistent energy efficiency. This supports sustainability objectives and reduces heating and cooling demands in harsh climate conditions.

Benefits for Urban Development

Urban planners see self-healing materials as a practical tool for reducing the environmental footprint of city growth. Fewer repairs translate into reduced emissions from construction machinery, less waste material and lower logistical impact. This aligns with 2025 European commitments to cut greenhouse gas emissions in infrastructure sectors.

Longer-lasting buildings require fewer refurbishments, which benefits both property owners and public authorities. Reduced demand for replacement materials helps stabilise construction budgets and supports circular economy strategies. Self-healing systems also support improved safety standards, as they mitigate the risk of structural defects that might otherwise go unnoticed until they become severe.

From residential properties to large commercial complexes, these technologies contribute to stable long-term performance. They allow city planners to model future development more accurately by predicting material lifespan with higher precision, supporting resilience-oriented design principles across modern urban environments.

Self-Healing Technologies in Machinery and Electronics

Self-repairing materials have also transformed the machinery and electronics industries. Flexible electronics, particularly those used in wearables and medical devices, now employ polymers capable of reconnecting electrical pathways when torn or punctured. This significantly improves device reliability and reduces electronic waste. Research centres in Germany, Japan and South Korea have contributed heavily to developing these conductive self-healing materials.

In automotive and industrial machinery, polymers that repair scratches and minor structural damage have become commonplace. These materials react to temperature changes or light exposure, triggering internal chemical bonding that restores surface smoothness. As a result, vehicle components and industrial casings experience longer operational lifespans, while maintenance downtime decreases.

Even battery technology benefits from self-repair mechanisms. Silicon-based anodes used in high-performance lithium batteries tend to crack during charging cycles. Self-healing binders help maintain electrode stability, extending battery life and improving overall efficiency. This supports the rapid expansion of electric mobility and renewable energy storage solutions worldwide.

Impact on Equipment Reliability

Machines equipped with self-repairing components offer more predictable performance and lower operational risks. In industrial manufacturing, this contributes to smoother production cycles and reduced downtime caused by mechanical failure. By 2025, such systems are increasingly adopted in automated facilities seeking reliable, low-maintenance solutions.

For consumer electronics, self-healing polymers provide resilience to everyday wear. Smartphones, tablets and earphones now incorporate materials capable of repairing microtears and surface abrasions. This prolongs the usability of devices and lowers repair costs, which contributes to reduced electronic waste—a major environmental concern.

In heavy-duty sectors, including logistics and energy, equipment built with self-healing components supports uninterrupted operations. This ensures higher safety standards and measurable financial benefits for operators who rely on durable, fault-tolerant machinery.