Promising Directions for the Development of 3D Printing

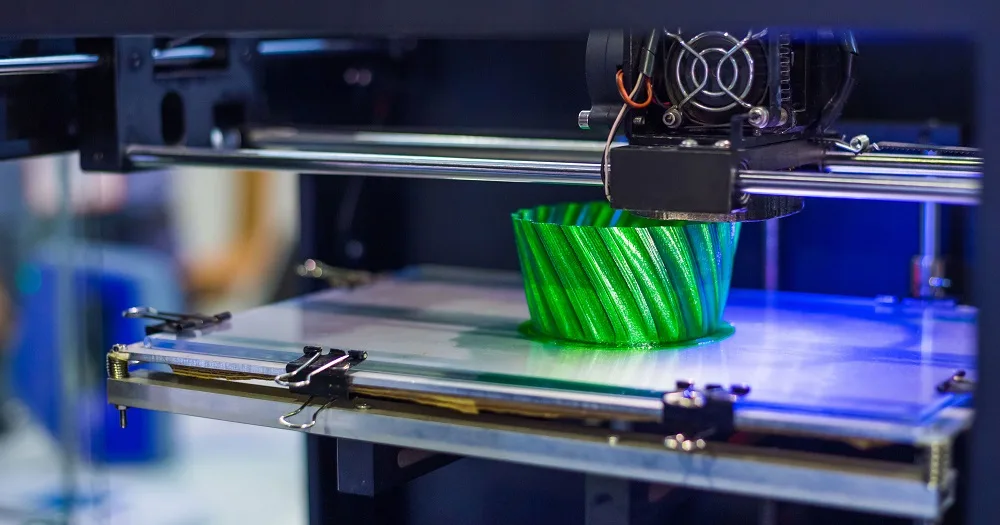

3D printing technology, once a niche field with limited applications, has rapidly evolved into a pivotal innovation shaping numerous industries. Its flexibility, efficiency, and ability to create complex designs on demand make it a key player in the future of manufacturing.

Relevance of 3D Printing

The relevance of 3D printing today cannot be overstated. It has transcended its initial applications of prototyping and small-scale manufacturing to become integral in industries such as aerospace, healthcare, automotive, and construction. The technology’s ability to produce parts with complex geometries that are difficult or impossible to achieve with traditional manufacturing methods has opened new avenues for innovation. Additionally, 3D printing promotes sustainability by reducing waste and allowing for the use of eco-friendly materials.

Prospects for 3D Printing in Various Fields

Healthcare

In healthcare, 3D printing is revolutionizing personalized medicine. Custom implants and prosthetics tailored to individual patients’ anatomy not only improve patient outcomes but also reduce recovery times. Beyond prosthetics, bioprinting—3D printing with cells and biomaterials—is paving the way for printing tissues and organs, potentially solving the organ donor shortage crisis. Even Druckgluck online casino has found application by printing figurines on a 3D printer.

Aerospace and Automotive

The aerospace and automotive industries benefit from 3D printing through the creation of lightweight, high-strength components. This leads to more fuel-efficient vehicles and aircraft, contributing to environmental sustainability. The ability to produce parts on demand also reduces inventory costs and streamlines the supply chain.

Construction

In construction, 3D printing is being used to print entire buildings and structures, significantly reducing labor costs and construction time. This method also allows for unique architectural designs and could play a crucial role in providing affordable housing solutions.

The Future of 3D Printing

The future of 3D printing lies in its continual integration into mainstream manufacturing processes. Advancements in speed, material variety, and printing resolution are expected to broaden its applicability. Moreover, as the technology becomes more accessible, it will democratize manufacturing, enabling small businesses and individuals to produce customized products locally.

Unexpected Possibilities of 3D Printing

3D printing’s versatility leads to unexpected applications, from printing electronics directly onto surfaces to creating food. In the culinary world, 3D printed food offers potential solutions for sustainable eating by using alternative ingredients like proteins from algae or insects. In electronics, the ability to print conductive materials opens up new possibilities for integrating electronic functionality into various products, further blurring the lines between digital and physical manufacturing.

Revolution in Materials

Perhaps the most significant area of development in 3D printing is the revolution in materials. The ongoing exploration of new materials—from advanced polymers and metals to graphene and beyond—continues to expand the possibilities of what can be printed. These materials not only offer improved properties such as strength, flexibility, and conductivity but also introduce functionalities that could lead to self-healing structures, shape-shifting objects, and even 3D printed devices that can monitor health or environmental conditions.