Construction Robots: Automated Housing Development on Mars and Earth

In the face of rapid urbanisation and the growing interest in space colonisation, automated construction technologies are becoming indispensable. Robots designed for building applications now offer efficient, cost-effective solutions for both terrestrial housing projects and extraterrestrial settlements. This shift from manual labour to robotic automation opens up new opportunities for creating sustainable infrastructures on Earth and preparing habitats for missions to Mars.

Progress in Terrestrial Construction Automation

On Earth, robotics are redefining how homes and buildings are designed and assembled. Technologies such as 3D concrete printing, autonomous excavators, and robotic bricklayers are reducing reliance on traditional labour-intensive processes. These innovations speed up construction timelines, reduce material waste, and enhance safety by minimising human exposure to hazardous conditions.

One notable example is the use of mobile 3D printers that construct entire houses in under 24 hours. Companies like ICON and Apis Cor have successfully demonstrated that automated systems can handle structural walls with precision and minimal human oversight. These advancements are not only efficient but also enable rapid deployment of affordable housing solutions in disaster zones or underserved areas.

Moreover, digital twin technology allows for real-time simulation and monitoring of construction sites, ensuring that robotic systems follow architectural plans accurately. This integration of AI-driven planning and robotic execution is setting new benchmarks in the construction industry, with scalable applications from urban developments to remote settlements.

Challenges in Integrating Robotics on Earth

Despite the benefits, integrating robotic systems into the construction sector faces hurdles. Legacy infrastructure, high initial investment costs, and a workforce not yet fully trained to operate these technologies slow down adoption. Furthermore, adapting robots to diverse environments and unpredictable weather conditions can affect performance and reliability.

There is also a cultural component—many construction companies are hesitant to replace human workers with machines due to labour union concerns or public perception. Addressing these barriers requires collaborative frameworks between technology providers, educational institutions, and government agencies to ensure a just transition toward automation.

Legal and safety standards must also evolve. Ensuring that autonomous machines comply with construction codes, maintain structural integrity, and handle complex site logistics is a non-trivial task. These factors highlight the need for rigorous testing and regulatory frameworks.

Robotic Construction for Martian Habitats

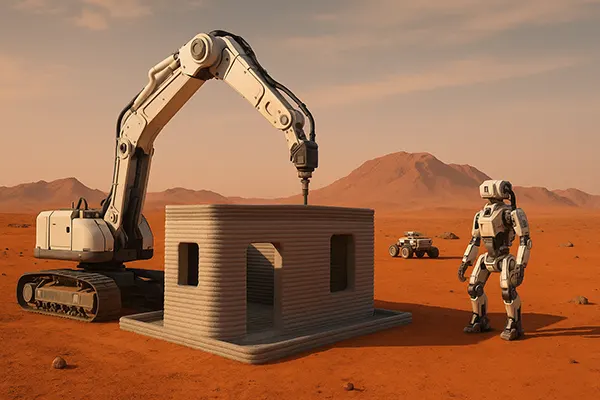

Robotic construction becomes even more critical in extraterrestrial contexts, especially Mars, where human presence is limited and the environment is hostile. The key approach here is in-situ resource utilisation (ISRU), where robots build habitats using local materials such as regolith to minimise cargo from Earth. NASA, ESA, and private firms are investing in robotic systems that can autonomously set up base infrastructure before astronauts arrive.

Advanced prototypes include semi-autonomous rovers equipped with excavation arms, robotic arms for assembly, and mobile 3D printing units. These machines are programmed to create pressurised habitats, radiation shields, and landing pads. The European Space Agency’s “Project Olympus” and NASA’s partnership with ICON for Martian construction are examples of how terrestrial robotics are being adapted for space missions.

Another consideration is redundancy. Robots must be capable of operating under limited supervision, handling maintenance, and adapting to unforeseen environmental variables. Energy efficiency is also vital, as systems must work within tight power constraints, relying on solar or nuclear sources in Martian conditions.

Designing for Autonomy and Survival

In Mars’ thin atmosphere and extreme temperatures, robotic construction systems must be extremely resilient. Unlike Earth, where human intervention can correct errors, Martian robots must complete tasks autonomously and correct deviations without human assistance. This calls for integrating AI and machine learning to help robots make real-time decisions.

Habitat designs are also influenced by environmental constraints—structures must withstand thermal fluctuations, high radiation, and dust storms. Robotic systems need specialised components to function reliably in low-gravity and abrasive conditions. Modular designs allow habitats to expand as needed while maintaining airtight integrity and structural safety.

Testing for these scenarios happens in analogue environments like the Mars Desert Research Station in Utah and ESA’s LUNA facility. These simulations validate how well robots can handle material sourcing, habitat assembly, and adaptation to terrain.

Bridging Terrestrial and Extraterrestrial Innovation

The synergy between robotic construction on Earth and Mars is mutually beneficial. Lessons learned from Mars missions accelerate innovation in terrestrial construction, particularly in remote and hazardous environments. Conversely, advancements in Earth-based automation support the design of efficient, compact systems ideal for space missions.

For instance, developing dust-tolerant components and low-maintenance systems for Mars has led to improved durability in Earth-based machinery. Similarly, the modular construction approach used for space habitats is now being adapted to rapidly build emergency shelters or medical centres in crisis zones on Earth.

This reciprocal relationship enhances global resilience. As climate change and population pressures intensify, leveraging space-derived technologies could transform how we approach housing and infrastructure challenges across diverse geographies.

Future Outlook for Global Construction

Looking ahead, robotic construction will become a cornerstone of urban planning and space exploration. Governments and private sectors are investing in research that supports cross-pollination of technologies between Earth and Mars. Initiatives like NASA’s Centennial Challenge and ESA’s Hera mission foster innovation and collaboration in autonomous construction.

Education and training will also play key roles. Universities and vocational institutions must adapt curricula to prepare the next generation of engineers and technicians to work alongside and programme advanced robotic systems. Workforce reskilling will be essential to ensure equitable integration of automation technologies.

Ultimately, robotics is not about replacing humans but enhancing our capabilities to build safer, smarter, and more sustainable environments. Whether in urban landscapes or the Martian frontier, construction robots are shaping the future of human habitation.